Whitepaper: Air pre-heating in heat recovery systems for home ventilation

⏱ approx. 8 minutes

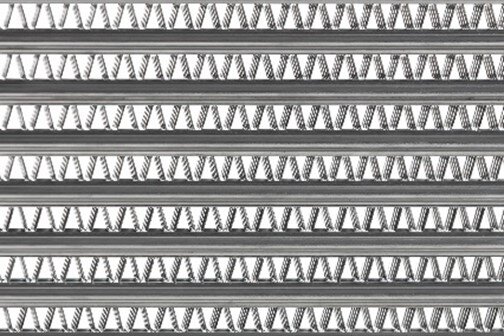

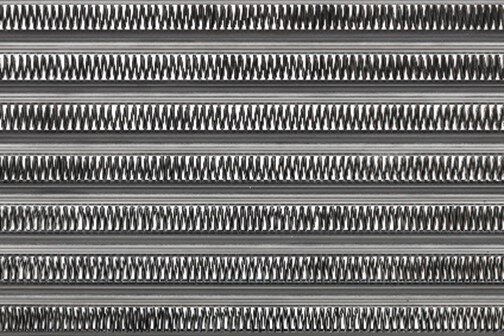

“The patented delta-shaped fin reduces the pressure drop to a minimum.”

WHY DO HEAT RECOVERY SYSTEMS NEED AIR PRE-HEATING?

Heat recovery in ventilation systems is a key factor complying with the energy requirements of low-energy houses. Heat exchangers are installed for this purpose. These preheat the supply air by using the warm exhaust air in winter and even cool the supply in summer.

If the temperature of the supply air drops below freezing point in winter, the heat exchanger can freeze, and its efficiency drops.

PROJECT GOAL

To keep the integrated heat exchangers free of ice and thus effective even below freezing point, insulated air heaters (HRP) are used which keep the air temperature above freezing point.

CUSTOMER / INDUSTRY

For several years now, DBK has been aiming to become a leading solution provider for air pre-heating. Meanwhile, DBK solutions are already integrated in many well-known heat exchanger systems.

DBK offers customised solutions that are precisely designed to meet the requirements of the customer's application.

SAFE AND EFFICIENT PRE-HEATING

When integrating a pre-heating element into a ventilation system, there are several important points to be considered:

Pressure drop is an important factor. If this is too high, the air generation will consume more energy, which accumulates costs over the entire year and must be paid for by the end user.

Furthermore, safety against the risk of fire is of utmost importance. Where there is a heater, hot surfaces are never far away.

Also, efficiency: The pre-heating registers should only provide enough heating power to increase the temperature of the supply air above the freezing point. Any further increase in temperature would be wasted energy.

TECHNICAL SOLUTION

To meet the high requirements for a low pressure drop in the ventilation industry, DBK has developed a new shape of heat-transferring fins. The patented delta-shaped fin reduces the pressure drop to a minimum.

To provide the heat, the DBK utilises the extremely safe PTC heating technology. This has the advantage that, due to a physical effect, a predefined temperature, for example 180°C, will never be exceeded. This eliminates the risk of fire due to hot surfaces, even in the event of a failure.

To achieve maximum efficiency, DBK additionally offers the integration of power electronics for certain applications. These are specially designed for the customer's application. This ensures that the air is only heated to the necessary temperature and that no energy is wasted.